Written by Rocco Petrizzo, TSI Contamination Control Application Specialist Europe, Middle East & Africa.

Introduction

Within Pharmaceutical and Biotech industries, environmental monitoring (EM) programs are put in place to ensure product safety and quality as well as patient safety. These EM programs typically include monitoring airborne non-viable and viable particles, as well as other environmental parameters such as humidity, temperature, and differential pressure. The BioTrak® Real-Time Viable Particle Counter can do all of this at the same time performing as multiple units in only one instrument.

For microbial monitoring, ISO 14698-1:2003 and ISO 14698-2:2003 are the International Standards that define methods for monitoring clean room spaces, and in addition give guidance for evaluating the performance of active air samplers, which are used for microbial monitoring. With active air samplers the sample is collected on an agar plate which is then incubated for several days before is being analyzed for the number of Colony Forming Units (CFU), which represent the number of colonies growing on a single agar plate. Using this method means waiting, typically 3-5 days, for results before product can be released and shipped to customers. So, the challenge for Quality Assurance professionals is that historically, the microbiological quality of the air cannot be determined in real time. It is not uncommon to wait at least several days to find out if a particle excursion detected by the nonviable particle counter may have contained viable microorganisms, which can affect the microbiological quality of the product. Even then, this information may prove to be inconclusive as active air sampling may have been performed intermittently during the critical process. All this time, valuable product, sometimes with a very short shelf life, may be sitting in the warehouse awaiting release.

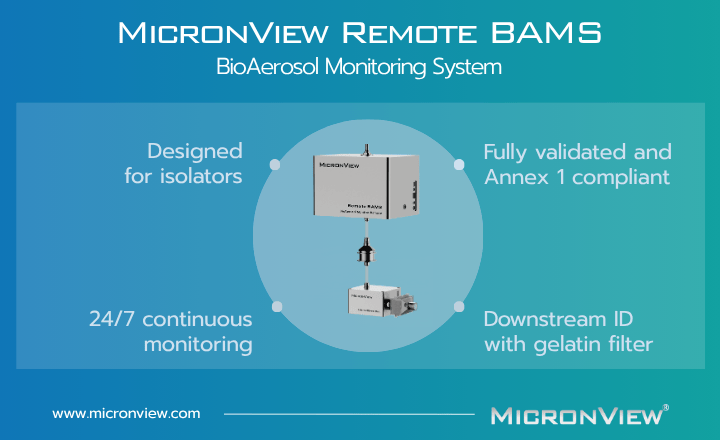

The BioTrak® Real-Time Viable Particle Counter is a full-featured Rapid Microbial Method (RMM) instrument that is able to detect viable and nonviable particles in real time. Follow-up off-line analysis is important since real-time optical analysis instruments detect microbial viability, but do not provide species specific information. The BioTrak® product incorporates a particle collection filter so the optically analyzed particles are available for subsequent speciation analysis. All of the particles analyzed by the BioTrak® detector’s viability discrimination optics are collected on the gelatin filter

that is easily inserted and removed from a holder accessed on the front of the instrument. This filter maintains microbial viability for over 9 hours, including during exposure to a continuous air flow (Scherwing 2007), and supports off-line identification of measured viable particles. As mentioned, an advantage this provides over conventional, fixed interval monitoring is that species identification can begin immediately when an excursion in viable particles is detected.

Use of Process Analytical Technology (PAT) such as real time instruments to detect particle contamination excursions outside of control limits can lead to significant cost savings by reducing product waste, delayed shipments, and personnel effort to identify and address contamination sources and improve your root cause investigation. With the TSI BioTrak® Real-Time Viable Particle Counters we can provide you with reliable, real-time detection of airborne viable contamination reducing the risk for Quality Control professionals in adopting this Rapid Microbial Method (RMM) technology. Finding the source of airborne microbiological contamination takes minutes instead of days or weeks.

The BioTrak®Real-Time Viable Particle Counter sizes and counts particles in exactly the same way as conventional airborne particle counters, like the TSI AeroTrak® Portable Particle Counter. The airborne particle counting sensor has a high flow rate of one CFM (28.3 LPM) and six particle size thresholds ranging from 0.5 μm to 10 μm, and the sensor calibration meets all the requirements of ISO 21501-4. This means that the BioTrak®Real-Time Viable Particle Counter can report total particle counts as defined in EU GMP Annex 1 and FDA aseptic processing guidelines and will be directly comparable with historical air cleanliness data.

The BioTrak® detector logs total and viable particle counts in six size categories, with selectable time resolution from one second to multiple hours. The BioTrak® detector supports downloading data to a USB flash drive for transfer to user reporting, LIMS, or SPC software.

Real-time response means product, potentially at risk of airborne microbiological contamination, can be immediately segregated. End users will now know the exact moment in time when an airborne viable particle excursion took place. A real-time understanding of the in-process microbiological quality of the air is aligned with the principles of ICH Q8 Quality Risk Management (QRM), ICH Q9 Quality by Design (QbD) and Process Analytical Technology (PAT).

Benefits of Real-Time Viable Particle Counting

RMM techniques offer significant potential benefits to manufacturing spaces concerned with environmental microbiological contamination. The BioTrak® Real-Time Viable Particle Counters offer the ability to detect the presence of viable particles in real time, compared to the traditional active air sampling and compendial culture based count methods that require 3 to 5 days of incubation and analysis. The BioTrak® Real-Time Viable Particle Counter provides:

- High resolution trending of microbial particle levels in the manufacturing environment

- Instantaneous notification of microbial contamination events, which enables:

- Segregation of potentially exposed product

- Environmental alert and action level alarms

- Rapid initiation of root cause investigation

- Process Analytical Technology (PAT) based process control input

- Potential for real-time product release

- Real-time feedback to support personnel training on proper clean room practices

- Ability to “sniff” air to locate contamination sources

CONCLUSIONS

For production of parenteral pharmaceuticals, real-time Laser Induced Fluorescence (LIF) counting of airborne microorganisms can provide additional information leading to multiple benefits over conventional monitoring methods. As shown by this data:

- Viable airborne microorganisms can be discriminated and counted in real time by LIF technology.

- Continuous viable and total particle monitoring show contamination events that are not captured by intermittent monitoring of active air samplers.

- Total particle count increases are not necessarily indicative of viable particles increases, thus total particle counts alone is inadequate data without the viable count data to allow full understanding of microbiological contamination control.

- In LIF instruments with collection filters, the airborne microorganisms that were optically analyzed can be identified via laboratory speciation. In addition, with a longer sample time, potentially more microorganisms will be available for analysis.

These new methods offer many advantages and must be evaluated individually for their application to a specific concern or assay. The regulatory effect on established product and process specifications and levels must be completely evaluated because the apparent number of microorganisms in a sample may be affected by the method of analysis.

For more information on how BioTrak can help your root cause investigations visit: www.tsi.com/biotrak-9510/