- Biotech Fluidics installed two DEGASi® Plus semi-prep 6-channel degassing systems on a diagnostic kit manufacturing line, reducing reagent dispensing issues by almost 77%.

- The systems were installed to address issues of chilled solutions warmed up during the dispensing procedure where temperature increase, negative pressure transient and bubble nucleation points led to outgassing

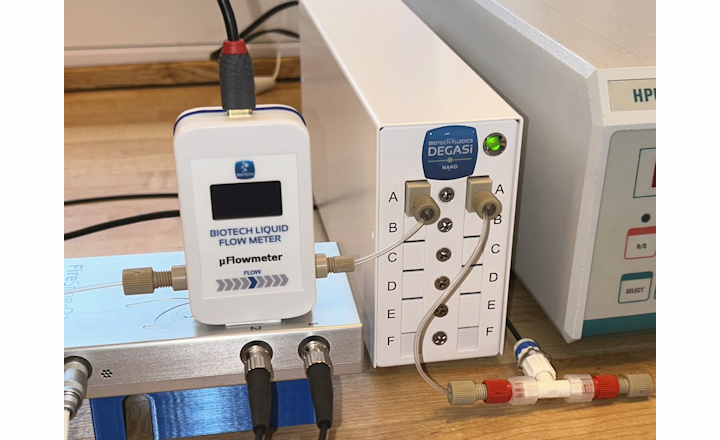

- Equipped with 1-6 chambers and a biocompatible flow path of 925 microliters for both aqueous and organic fluids. The DEGASi® Plus semi-prep degasser is designed to remove gas bubbles from processes operating at flow rates of 3-6 mL/min.

Biotech Fluidics report how installation of two DEGASi® Plus semi-prep 6-channel degassing systems on a production line, has enabled a diagnostic kit manufacturer to almost eliminate inaccurate reagent dispensing issues.

Dispensing precision is critical to the performance of modern diagnostic kits, where repeatability and accuracy in the amount of reagent dispensed form the basis of reliable results. Collaborating closely with the customer, Biotech Fluidics identified in the reagent kit manufacturing process that chilled solutions warmed up during the dispensing procedure as they moved through the fluidic system - from the bulk supply to the dispensing nozzle.

Fritiof Pontén, CEO of Biotech Fluidics commented “The increase in temperature, as well as negative pressure transient, and bubble nucleation points within the system resulted in outgassing. This unwanted effect led to bubble formation in pumps and check valves, lowering the dispensing precision in the kit manufacture. Such deviation in the dispensed amount of reagent solutions negatively affect the validity, economics, and possibly even the regulatory approval of a product.”

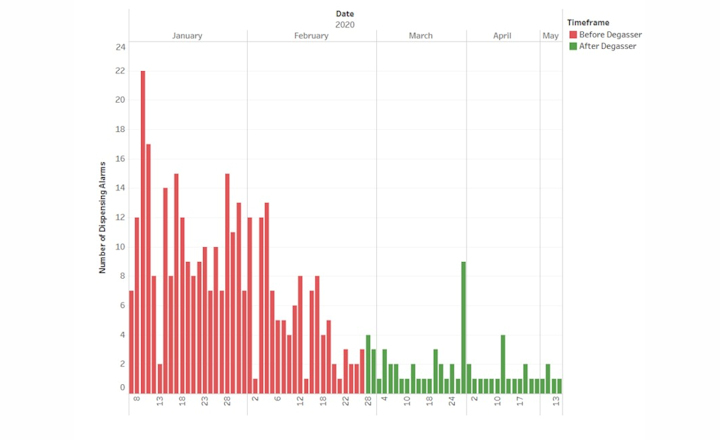

He added “Our implemented solution of continuous inline degassing with Teflon® AF membranes effectively removed dissolved gases from reagent solutions thereby greatly increasing precision and reducing dispensing errors by 77%. Before the installation of the two DEGASI PLUS systems the reagent kit manufacturer observed significant dispensing errors in 2% of all samples. Installation of our in-line degassing systems eliminated this source of dispensing errors.”

The DEGASi® Plus semi-prep degasser is designed to efficiently remove gas bubbles from processes operating at flow rates of 3-6 mL/min. This high-performance inline degasser is equipped with 1-6 chambers with a biocompatible flow path of 925 microliters for both aqueous and organic fluids. For further information on the DEGASi® Plus semi-prep degasser please visit https://biotechfluidics.com/products/degassing-debubbling/degasi/degasi-plus/degasi-plus-semi-prep/

To discuss the development of an inline degassing system for your diagnostic kit production line connect directly with Biotech Fluidics using the Request Information button below.