Safety first: Whatever beverage you produce – beer, wine, bottled water, soft drinks, or spirits - you cannot afford to compromise on quality. Sartorius helps you meet the industry’s growing challenges with ever-increasing levels of safety, process optimization and quality control as well as legislation demands.

Easy-to-use, up-to-date, ready-to-go: We keep your business flowing.

Count on It. Quality Control by Sartorius Sets New Standards.

Ask the Sartorius Experts for the solutions in your Beverage QC process Discover Solutions:

With several decades of experience in the food and beverage market, Sartorius has developed a range of specific products, addressing the clarification, filtration and microbiological control steps along the differing beverage industry process chains.

The company has studied and developed solutions tailored to each of these beverage segments: Beer, Bottled Water, Wine, Spirits & Soft Drinks.

Sartorius could offer a variety of applications and solutions for:

- Moisture Determination - fast and reliable moisture analysis for the widest variety of samples

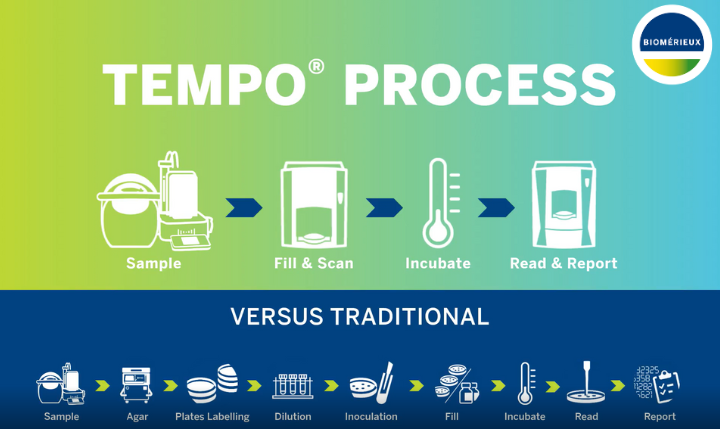

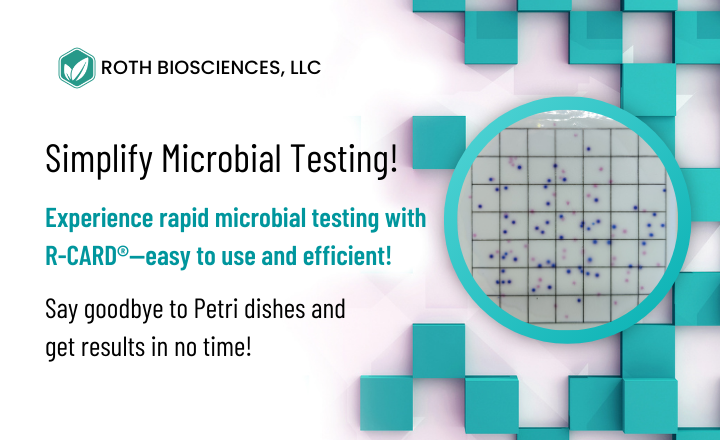

- Spoilage Detection - using a time saving alternative to agar plates to detect spoilage organisms such as Lactobacillus brevis, Lactobacillus lindneri and Pediococcus damnosusas well as molds, wild strain yeasts and Saccharomyces species

- Water Testing - improve the workflow for testing of water supplies for your beverages

- Analytical QC - tools for sample preparation of raw materials, in-process sampling and final product release

- Air Monitoring - with a portable device to monitor microbiological air quality in the production area and at the filling line

- Check Weighing - accurately control your actual contents or nominal gross weights

Download the Brochure: High Quality Solutions for High Quality Beverages now