Prepared media manufactured off-site by a media specialist are now an essential tool in the pharmaceutical industry. A manufacturing-based lab may need to buy in thousands of plates every year for different purposes, from in-process testing to monitoring of personnel and the manufacturing environment. The new EU Annex 1 guidelines will likely see an increase in the number of plates needed to meet revised requirements for finger dabs and monitoring cleanroom clothing.

However, the quality of plated media is so important for sterile medicine production, that it would be a mistake to consider them as simply consumables. Serious quality or sterility issues may cost expensive downtime to companies, which need to be prepared to change supplier altogether, if necessary.

In this exclusive interview with rapidmicrobiology, we asked Derek Lancashire, BD’s Global Platform Director of Industrial Microbiology, to give us a few recommendations on when companies should consider changing media supplier, and how to prepare a cost case for the change.

When should a company consider changing media supplier?

There are three types of critical issues that justify a change.

One is contamination. Simply put, a pharmaceutical company cannot take a contaminated plate into their clean room. Having a sterility failure on a product means you may have to do a full investigation, which can cost hundreds of thousands of dollars. Ultimately, you may have to discard entire batches and that could cost millions.

The other is disruptions in supply. Pharmaceutical labs are so dependent on plated media that without plates they simply cannot manufacture.

The third critical issue is inconsistent quality, whether it’s the performance of the media, or the product arriving to the facility following bad storage conditions.

How should a pharmaceutical company evaluate a potential new media supplier?

When you choose a supplier for your plated media, you're making a very large purchase for an extended period, so you really need to assess the manufacturer as a whole. The first step is auditing their facility to ensure it is state-of-the-art. At BD we're very proud to have our pharmaceutical partners come to our facilities, because we think we have a lot to show them.

More generally, you should assess how they manage quality. For example, they should have a strong notification program, where they notify customers in advance of any important change in the product. Other aspects are how they handle investigations and respond to complaints, their logistic capabilities and their quality standard accreditation like ISO 13 485 and ISO 9001.

Regarding the product, there are two important aspects to look at. One is the Sterility Assurance Level of the media. Plated media are often used to ensure the cleanliness of the environment in which products are manufactured, so sterility is very important. The other is performance, which should be assessed by testing different lots of media and making sure that they obtain repeatable performance and are compliant with USP standards.

What’s the best way for a quality manager to build a cost case?

Changing media supplier takes resources, so experiencing one or more of those three critical issues would be a compelling reason to change.

An important part of the ROI, however, is risk aversion. If you are going to be out of plates and have to stop production for a day, what would that cost you? If you had a contaminated plate in the clean room and you contaminate your product, what would that cost you?

Sterility plays an important role in this. I think some of the competitive advantages that BD has, is that we claim a Sterility Assurance Level (SAL) of 10-6 in some areas and 10-5 in other areas, and we stand behind that claim.

For example, a site that operates on a three-shift schedule may need 123 plates per day (41 per shift). If the plates’ SAL is 10-6, statistically, the odds of taking a contaminated plate into that clean room, are 0.045 in a year. If you don't make any claim on the plate, as it's irradiated you would have a SAL of 10-3, with a chance of taking 40 contaminated plates into a clean room over a year.

How are the proposed changes to Annex I of GMPs for medicinal products going to impact on the use of plated media and RMM methods in the pharma industry?

In general, I think most European companies are pretty close to already following the new regulations, but many of those in the US that export to Europe are not.

From what I understand, right now the recommendation is that personnel are tested every time they leave the clean room. That will mean a considerable increase in plated media usage.

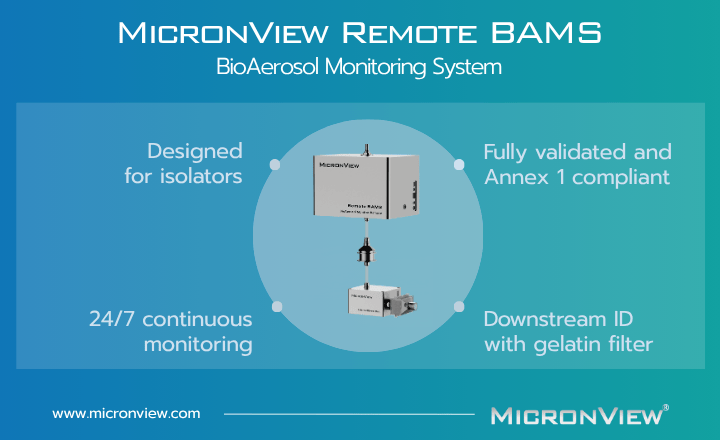

As far as RMM is concerned, it's been talked about for a long time. The possibility of having automated sterility testing and releasing the product in seven days, instead of fourteen is seen as the Shangri La in the industry. EM is of course another critical area.

Overall, I think RMM will continue to slowly gain traction, if anything because of the sheer volume of environmental monitoring samples. But I still think it will be based on compendium methods. For example, RODAC plates and 90-millimetre dishes will still be at the core of any RMM system. Also, I think companies will keep looking for open systems. Customers don’t want to use a proprietary plate.