Introduction Real-Time Airborne Viable Particle Counting is based on Laser Induced Fluorescence (LIF). Each particle sampled from the air is tested for viability. The principle is that metabolites present in living cells fluoresce when excited by a blue laser light source. Just like a non-viable1 particle counter, there is a result each minute. No more waiting, you know the moment a viable particle is there.

Understandably, senior company managers are eager for their organizations to evaluate this technology.However, when choosing a Real-Time Viable Particle Counter, the significant benefits gained by using it must be carefully balanced against risk.

A Real-Time Result A real-time viable particle counter samples continuously. The result, available every minute, is presented as the number of viable particles per unit volume of air.

Benefits of a real-time result include, immediate initiation of root cause investigations, detecting adverse trends quickly, fast risk based room release, and fewer interventions into RABS and Isolators to change agar plates.

It is better than waiting days or even weeks for a handful of plate count results, or, many days or even weeks to know if a state of control existed. Is an immediate result better? Does the data provided by a real-time viable particle counter represent the whole picture?

After all, even after a real-time viable particle counter has been validated2, a non-viable particle counter is still needed. EU GMP Annex 1:2008 and US FDA Aseptic Processing Guidance 2004, still requires non-viable or total particle counts measuring and documenting in controlled areas.

An Active Air Sampler (AAS) is still needed to sample air alongside the new rapid method. Otherwise, how can there be an opportunity to identify microorganisms associated with any excursions the real-time viable particle counter detects?

There are now three separate monitoring instruments to think about instead of two.

Real-Time Measurement Risk One potential risk when using three separate monitoring instruments sampling at the same location, is that they may not correlate. This is especially the case in clean areas where there are low concentrations of airborne particles.

A viable particle excursion event detected by a real-time viable particle counter will require investigation. Even if 5 days later the AAS plates come back with zero CFUs, and the non-viable particle counter detected no adverse trends at that time.

What level of confidence exists that it was a real bio-contamination excursion?

Is there a sampling bias towards the real-time viable particle counter? Are the AAS and non-viable particle counter probes positioned correctly? Did the real-time viable particle counter just happen to capture the particles carrying the microorganisms? Could the contamination be caused by Viable But Non Culturable organisms (VBNCs)? Was the excursion caused by fluorescing airborne particles or false positives?

Without an opportunity to analyze the sampled particles in the lab, a root cause investigation may be difficult. There may end up being more questions than answers.

The good news is that it does not have to be this way.

Confidence in the Real-time measurement To improve confidence in the measurement, real-time particle detectors exist that combine all three measurements into the same unit. Now there is one unit, one sample inlet. There is no sampling bias between three separate instrument sample inlets. The same air is analyzed.

The total number of 0.5 µm and 5 µm particles per cubic foot of air is continuously known. The number of viable particles per cubic foot of air is continuously known. Finally there is the opportunity to culture optically analyzed particles for identification. Meaning microbiologists can still do their work when a real-time viable particle counter detects an airborne viable excursion.

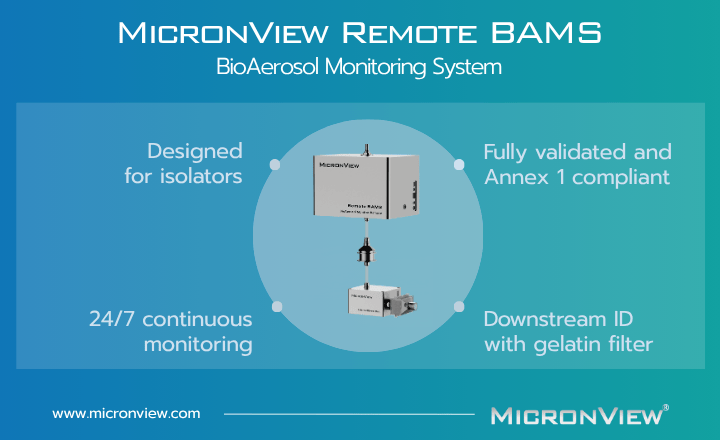

Plus, there is the added benefit of saving precious cleanroom space, and keeping the number of interfaces into critical areas such as RABS and Isolators to a minimum.

Conclusion Environmental monitoring technologies deliver trending information regarding the state of control of the environment surrounding the whole process. Has something in the facility changed? Change in the environment in a facility leads to increased risk to the product and process, and ultimately patient safety.

Detecting changes in levels of airborne microbiological contamination in real time in all areas of a life science manufacturing facility is now a reality.

Instruments such as TSI’s BioTrak Real-Time Viable Particle Counter detect airborne viable particles in real-time. Per the current EU and US FDA aseptic processing guidance, it monitors total (non-viable) particle counts at a flow rate of one cubic foot per minute. All via a single particle monitoring probe. Optically analyzed particles are collected on a filter validated to maintain microbial viability for over nine hours. Laboratory analysis is then performed using traditional growth based methods or an alternate rapid method.

1. A non-viable airborne particle counter sizes and counts all particles per ISO 21501-4 and ISO 14644-1. It does not matter whether the particle sampled is viable or non-viable, it is sized and counted. The instrument cannot tell the difference.

2. Validating a real-time airborne viable particle detector requires it to be tested in parallel with the existing method to establish a correlation. PDA TR #33: 2013 details valuable guidance on evaluating, validating and implementing Rapid Methods. USP <1223> draft proposes useful thinking and approaches.