Paperless QC Microbiology

Paper-based QC Micro laboratory processes can be expensive, error-prone, time and labor-intensive.

Visit the Lonza booth #310 at the PDA Global Conference on Pharmaceutical Microbiology to learn how the MODA-EM™ Solution, can enable organizations to automate quality control processes and access data in real-time to expedite investigations and use the data that they are capturing.

By combining automated scheduling, workflows, mobile data acquisition, device integration, and advanced analytics, the MODA-EM™ Solution delivers efficiencies across your organization.

Gain complete insight into your manufacturing operations.

Quickly access reports and trends on your quality data – at the click of a button.

Move to a review by exception workflow and enforce compliance to SOP’s and Data Integrity guidelines.

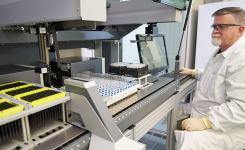

The MODA-EM™ Solution also easily integrates with commonly used instrumentation and media in the laboratory and enterprise solutions such as SAP and LIMS to ensure the seamless transfer of data.

The Next Generation Electronic Batch Record ![]()

The MODA-ES™ Electronic Batch Records Software Platform is a comprehensive solution that bridges the gap that currently exists between manufacturing and QC to provide a single batch record with an intuitive review and approval interface. With GMP compliance and tracking at its core, the MODA™ Platform combines data capture and error prevention with the flexibility to capture and trend key quality and performance metrics, both in the lab and on the production floor.

Poster:

During the 14th Annual 2019 PDA Conference on Pharmaceutical Microbiology attendees can learn about the Practical Applications of Data Integrity and Audit Trail Review.

With the prominent rise of electronic systems used in both laboratory and manufacturing processes, companies have been forced to educate staff and develop procedures on the use and management of these systems. For many years there was little guidance on the expectations from auditors on how to ensure that these systems are in compliance and remain that way. As auditors became familiar with the system use and maintenance, audit trails became a focus. Today, with audit trails the primary focus, companies must understand the expectations of the review and management of these audit trails.