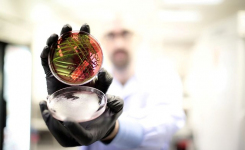

QC Microbiologists understand that an effective quality control process is not a simple paper exercise. A holistic approach must be taken, evaluating perceived risks in the design and planning process while actual risks are assessed in the qualification, start-up, and operational stages.

Following the issuance of the final version of the EU GMP Annex 1 in August, our Technology & Market Development team synthesized the 58-page document into three key elements to ensure your lab is in compliance with the new guidance, reduce human error, and, most importantly, create products that are safe for patients.

The requirements that may make an impact on your organization are:- Pharmaceutical Quality Systems (PQS), which includes the principles of Quality Risk Management (QRM) into sterile drug manufacturing. Developing an action plan requires accurate identification of the source of contamination. This can be accomplished by leveraging genotypic methods based on robust libraries like Accugenix®.

- A holistic approach to the Contamination Control Strategy (CCS) and a documented plan to keep your manufacturing environment under control. It is critical to audit the requirements of QC labs and how these new changes will affect the long term. Understanding the requirements and taking a practical approach to implementation of CCS is a must. Detailed analysis of where and how to start and what steps to follow should be considered for designing an effective plan.

- Aseptic Processing: Approach to contamination control can be extended to other products that are not intended to be sterile, such as certain liquids, creams, ointments, and low-bioburden biological intermediates.