- The final text of Chapter <86> endorses the general use of recombinant reagents for BET, including both recombinant Factor C (rFC) and rCR, and will be published for early adoption in November 2024, becoming official in May 2025.

- As the industry moves towards more sustainable practices, Charles River remains committed to providing modern solutions that meet the highest standards of quality and regulatory compliance.

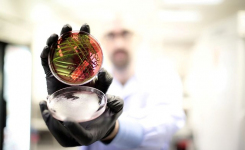

- Charles River's Endosafe® Trillium™ rCR technology offers significant advantages over single-enzyme recombinant alternatives.

- To facilitate the implementation of recombinant BET methods, Charles River offers the Endosafe® Trillium™ rCR Primary Validation package.

Recombinant Cascade Reagents (rCR), like Charles River’s Trillium, are the latest advancement in the field of Bacterial Endotoxin Testing (BET). A non-animal derived, three-enzyme reagent similar to Limulus Amebocyte Lysate (LAL), it’s suitable for detecting endotoxin throughout the pharmaceutical industry. Now, more than ever, companies strive to comply with the 3Rs principles and sustainability initiatives. With the industry and regulatory push toward animal-free and more sustainable alternatives in BET, this development will allow easier implementation of recombinant reagents for pharmaceutical manufacturers and quality control laboratories.

Recently, the US Pharmacopeia (USP) approved Chapter <86>, which endorses the general use of recombinant reagents for BET and includes both recombinant Factor C (rFC) and rCR. The final text of Chapter <86> will be published for early adoption in November 2024 and will become official in May 2025. This approval marks a pivotal shift in our industry and allows manufacturers the option to adopt a recombinant reagent more easily for their new biopharmaceuticals. In the past, there was little guidance for manufacturers on how to proceed when moving from LAL to recombinant reagents. The USP now requires a simple suitability test for any waters, in-process samples, raw materials, or products that are not currently included in a general monograph or notice, and while regulatory authorities may request additional supplemental data prior to acceptance, this procedure is much more straightforward than an alternate method validation.

The acceptance of recombinant reagents by the USP Expert Committee demonstrates a trust in both recombinant manufacturers and pharmaceutical manufacturers who have played a key role in generating scientific data proving the comparability and equivalence of recombinant BET methods to traditional LAL methods in many circumstances. Similar to LAL, recombinant reagents may not be suitable for all products. Therefore, it is key that pharmaceutical manufacturers continue to perform internal risk assessments, interference and enhancement screenings, and validations on their products. Greater understanding of BET methods comes as more data becomes available to regulatory agencies, and discussions are occurring globally on how best to harmonize the BET chapters. Both the Indian Pharmacopeia (IP) and the Korean Pharmacopeia (KP) are expected to follow the USP. However, the Chinese Pharmacopeia (ChP), Japanese Pharmacopoeia (JP), and European Pharmacopeia (EP) are still in discussions on how best to proceed.

Charles River is committed to supporting pharmaceutical manufacturers through this industry transition, and our team of experts is available to discuss how these changes may impact your operations and provide guidance on implementing the most suitable BET method. To facilitate your implementation of recombinant BET methods, we offer the Endosafe® Trillium™ Recombinant Cascade (rCR) Primary Validation package which includes validation protocols, results, and statistical analysis to simplify your implementation process. As the industry moves toward more sustainable and efficient test methods, we remain dedicated to providing modern solutions that meet the highest standards of quality and regulatory compliance.