Sustainability in laboratory operations is no longer just an aspiration; it is a necessity. Laboratories globally are striving to reduce their carbon footprints, minimize waste and adopt more eco-friendly practices. However, achieving these goals can be daunting, especially when it involves extensive changes to infrastructure and significant capital investment. One of the more accessible ways to enhance environmental stewardship is through responsible supplier selection.

In this interview with Dr Ursula Leuthold, Sustainability Coordinator at INTEGRA Biosciences, we learn how INTEGRA has made substantial progress towards reducing its CO2 emissions over the last 5 years, and how this success can help laboratories to meet their own climate change goals.

Q: What sustainability standard or certification should labs look for from suppliers?

Ursula: Labs should consider buying from suppliers that meet the international standard ISO 14001:2015, which defines the standards for an efficient environmental management system (EMS), i.e., better resource use, waste reduction and continual improvement. There's also the Science Based Targets initiative (SBTi) and IntegrityNext, which presents a sustainability reporting framework for small and medium-sized firms based on environmental, social and governance (ESG) criteria.

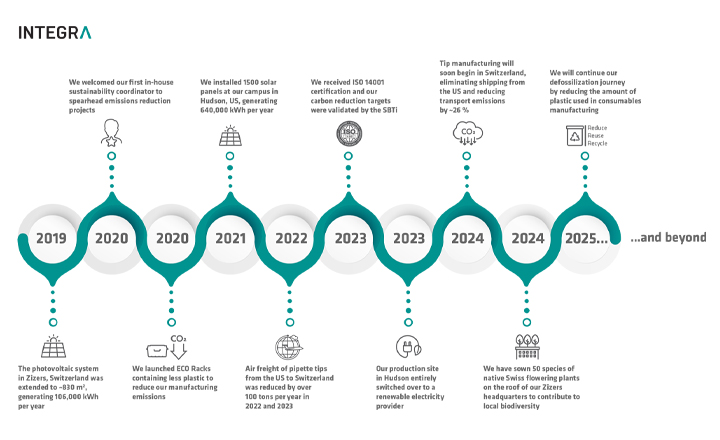

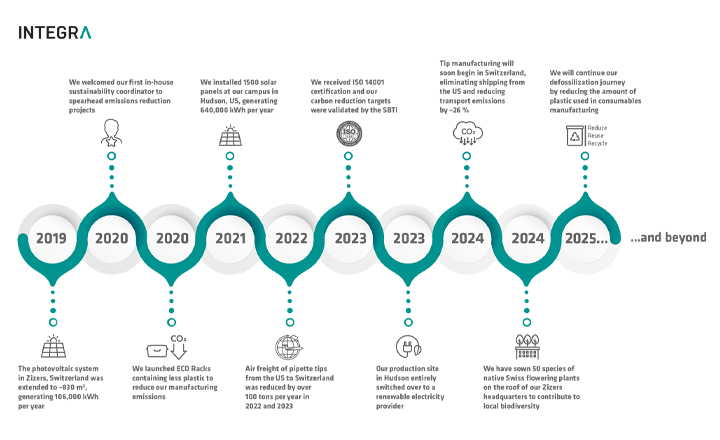

INTEGRA acquired ISO 14001 certification in 2023, and our SBTi reduction targets were certified in 2023. Our sustainability roadmap provides more information on the SBTi targets and what we've done to reach them. Our self-assessment on the supply chain monitoring platform IntegrityNext can be found here.

Q: How can working with INTEGRA as a supplier help labs to reach their sustainability targets?

Ursula: INTEGRA is committed to reducing its carbon footprint, so choosing us as a supplier also helps labs to meet their own environmental targets. Our production sites run on 100% renewable electricity, and our products are designed to be durable and flexible for a long working life. We also use energy-efficient components in product design, and avoid the use of hazardous chemicals where possible. In addition, we offer a number of sustainability-focused products to help labs keep their carbon emissions as low as possible, including:

- Low volume pipette tips in racks of 384, drastically reducing plastic waste compared to the industry standard 96 tip format.

- ECO racks for our EVOLVE, VIAFLO and VOYAGER pipettes, which use 60% less plastic than our standard pipette tip racks.

- GREEN CHOICE pipette tips rack inserts for use in combination with sturdy, reusable POPTOP bases to further reduce plastic use.

- Thin, disposable reservoir inserts – designed to work with reusable bases.

Click here for further information.

Q: INTEGRA has worked on emissions reduction for many years; what has the company achieved so far?

Ursula: We have committed to reducing our corporate greenhouse gas (GHG) emissions across the SBTi's three scopes, which cover different areas of the business.

Scope 1 includes all direct emissions from owned or controlled sources, such as business travel in company cars or the combustion of fuels in heating systems.

Scope 2 includes all indirect emissions from the production of purchased electricity consumed by the company.

Scope 3 includes all other indirect emissions within the supply chain, encompassing upstream processes during the production of raw materials and downstream processes such as the distribution, use, and end-of-life treatment of products.

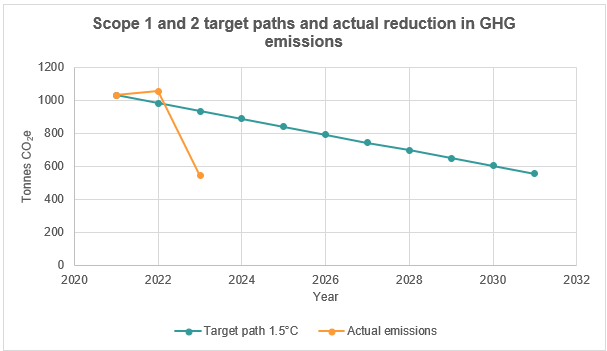

INTEGRA is committed to:

- reducing absolute Scope 1 and 2 GHG emissions by 46.2% by 2031 (compared to 2021);

- increasing active annual sourcing of renewable electricity from 48% in 2021 to 100% by 2030;

- reducing scope 3 GHG emissions from purchased goods and services, fuel and energy-related activities, upstream transportation and distribution, waste generated in operations, business travel, employee commuting, use of sold products, and end-of-life treatment of sold products by 51.6% per million CHF value added by 2029 (based on 2019 figures).

By 2023, we had already hit our first target to reduce scope 1 and 2 GHG emissions by 46.2% from 2021 – 8 years ahead of schedule! This was achieved by transitioning all production facilities to exclusively renewable electricity.

Figure 1. Reduction of GHG emissions by INTEGRA, in line with scope 1 and 2 of SBTi.

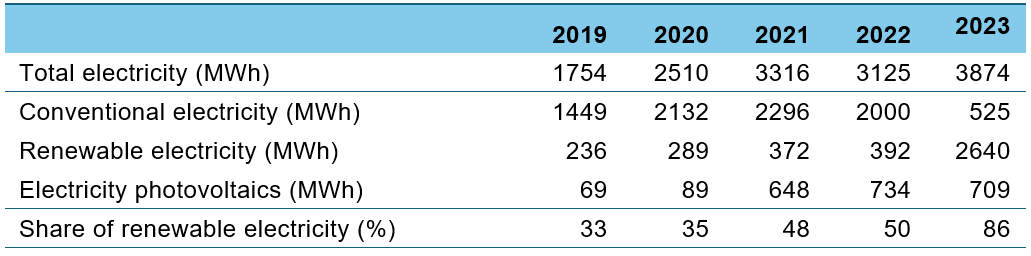

We are also on track to meet our second target of increasing the share of renewable electricity to 100% in 2030, going from 48% in 2021 to 86% in 2023 (Table 1).

Table 1: Electricity consumption and share of renewable electricity at INTEGRA.

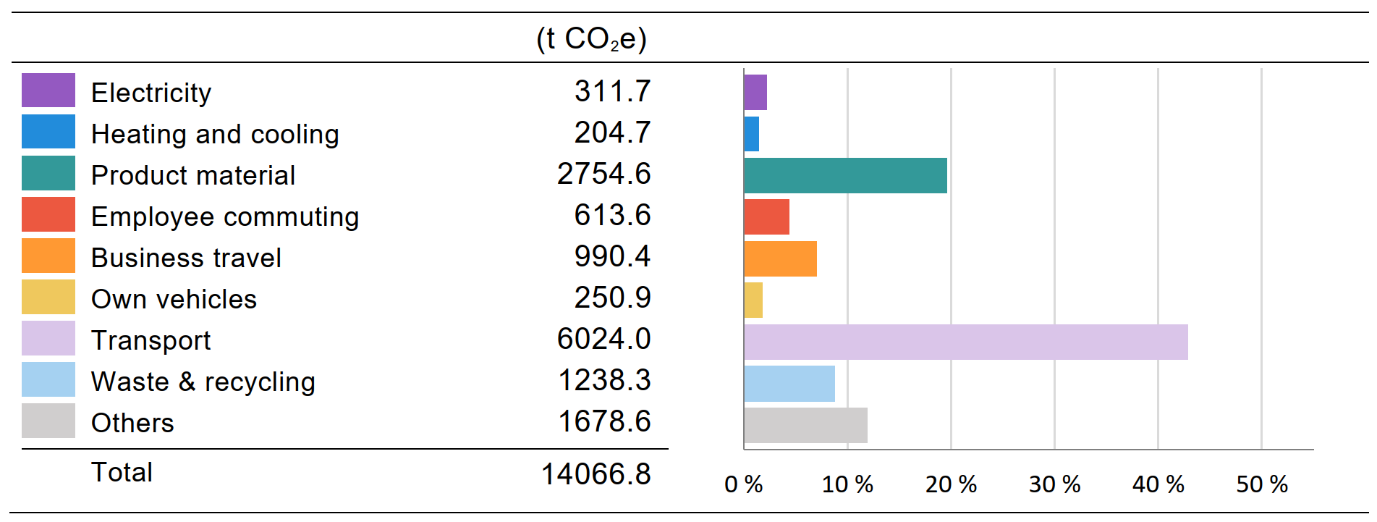

We are continually working on our third target; to reduce our supply chain emissions. The transport of raw materials and products accounts for 43% of our CO2 emissions, and 75% of this is attributed to the transport of pipette tips. Reducing pipette tip transport emissions is, therefore, one of our top priorities, and we have constructed a second injection molding facility at our Swiss headquarters for this.

Historically, we molded all of our tips for customers worldwide in the US. From 2024, tips for European customers will be produced in Switzerland, significantly shortening transport routes. This will help us to reduce our corporate transport emissions by an estimated 26%. More details on this can be found here. Moreover, we will also further reduce and de-fossilize our plastic use and favor local suppliers who use renewable energy sources.

Q: What documentation is available to labs to ensure that their supplier is not greenwashing?

Ursula: It is vital that labs ensure that their chosen supplier can fully justify their environmental claims with detailed supporting documentation. For instance, INTEGRA can demonstrate the following:

- The Myclimate Foundation has supported INTEGRA since 2020 in continuously monitoring the impact of our global operations according to the Greenhouse Gas Protocol. These reports can be downloaded here

- INTEGRA has received ISO140001 certification, which requires continuous improvement and annual audits, can be accessed here

Q: Which measure has had the biggest impact in reducing CO2?

Ursula: Our hotspots for emissions are transport and product materials. The use of plastic for tip racks, and their transport, makes up most of our emissions.

Figure 2. The total CO2 emissions generated from company activities in 2023.

Figure 2. The total CO2 emissions generated from company activities in 2023.

Here's what we've done to reduce this problem:

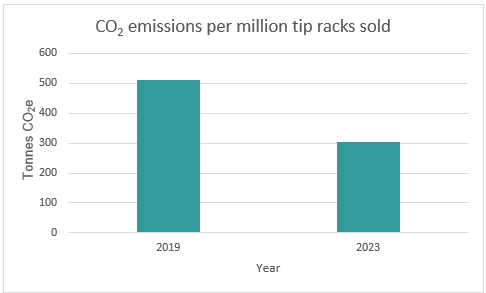

Launched ECO racks: These racks contain 60% less plastic than our previous racks. This has reduced CO2 emissions generated by manufacturing pipette tips for handheld devices by 41% per million racks sold between 2019 and 2023.

Figure 3. The reduction in CO2 emissions from INTEGRA after launching ECO racks.

Reduced air freight and used more sea freight: We have reduced the annual volume of goods transported by air freight from 436 t in 2021 to 207 t in 2023, by transporting goods by boat instead. This mode of transport generates approximately 250 t fewer carbon emissions than air freight.

Open a second tip molding facility in Switzerland: As explained above, our new tip production facility in Zizers will allow us to manufacture our pipette tips for European customers locally, eliminating the need to ship them from the US.

It is important to remember that the reduction in GHG emissions is only based on measures that INTEGRA has put in place. As the whole industry is focused on implementing sustainable practices, it is likely that measures taken by our partners – such as transport companies and material providers – to reduce their scope 1 and 2 emissions will further minimize our scope 3 emissions.

Q: Where will INTEGRA go from here? Is there more scope for improvement?

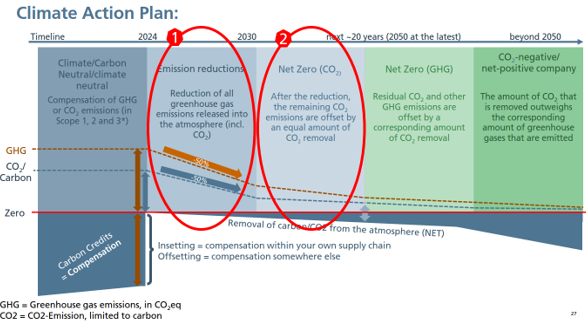

Ursula: We have validated the most ambitious 1.5 °C near-term, long-term and Net-zero targets to SBTi and are participating in the Business Ambition for 1.5°C campaign. This means that we are pursuing a concrete climate action plan. By 2030, we will have reduced all of our emissions as much as possible, and will be purchasing biocircular or CO2-based raw materials obtained through carbon capture and utilization (CCU) practices that remove CO2 from the atmosphere using renewable energy. From 2030, the remaining emissions must also be removed from the atmosphere through offsetting.

We will continue following this SBTi path, and our long-term goal is to achieve net zero across the whole company. This may take longer to achieve in areas where our sales offices are located in rented buildings, as we are not permitted to switch over to renewable heating and electricity sources or make structural changes – such as improving insulation – in these properties.

However, we won't let that hinder our progress, and we'll continue to make positive changes wherever we can to achieve our net zero goal. We are also working to achieve scope 3 emissions targets by addressing the following hotspots.

Hotspot 1: Transport of disposables - from 2024, we will produce products closer to customers, e.g., in the US for the US and in Europe for Europe. Moreover, we will further reduce the use of air freight.

Hotspot 2: Product materials - Projects to further reduce the amount of plastic in our consumables are in the pipeline, and we're working on a defossilization strategy.

Hotspot 3: Travel - we will switch our company fleet to electric cars, and provide charging stations for employees to encourage them to buy electric vehicles too. This has already been achieved in Switzerland with 40 new charging stations, and we will replicate this in the US.

If you want to discover how using INTEGRA Biosciences liquid handling instruments and consumables can help your laboratory meet environmental goals, use the Request Information button below.

About the Author