With rapid microbiology results now readily available to most dairy and beverage producers, the opportunity for a competitive advantage depends upon senior management teams translating faster results into real-time action. So, how do senior management teams put those fast results into real-time action? How can this data be used to make informed decisions and improve quality and production outcomes? This agility can be especially valuable in high-demand markets where fast turn-around times are essential to meeting consumer expectations and market deadlines.

In dairy or beverage manufacturing plants, contamination by spoilage or pathogenic microorganisms can arise from various sources, such as incoming raw materials, the filling line and equipment, or staff. By employing rapid microbiology testing, manufacturers can release products faster or quickly detect issues and deviations to identify sources of contamination so that corrective measures can be implemented promptly, minimizing the impact on production volumes.

RMM technologies are strategic investments that require capital investment and require a company-wide commitment to maximise its effectiveness and achieve the best return.

In this interview with Gaulthier Pesneau, Marketing Manager for Dairy & Plant Based Industry at bioMérieux, and Franck Andrieux, Marketing Manager for Beverages Industry at bioMérieux, we discuss how solutions for microbiology can foster inter-department collaboration between operations, quality, and supply chain teams, generate shareable insights, and improve efficiency to deliver that competitive edge for dairy, plant-based, non-alcoholic beverages, wine and beer manufacturers.

Q: What do we mean by ‘rapid microbial monitoring’, and where is the value for Dairy and Beverage industries?

Franck Andrieux: Firstly, ‘rapid’ refers to achieving a faster ‘time-to-result’ than would normally be possible using “traditional microbiology testing techniques”. These typically focus on reducing the time-to-result of a test to release a product faster, to save money by reducing storage costs, preventing costly recalls and help protect brand reputation.

However, while rapid analysis in the lab remains important, the real game-changer lies in going ‘further’ - i.e. focusing on the entire production lifecycle, whereby manufacturers can significantly improve their efficiency and bottom line.

This shift in focus brings several benefits:

- Enhanced productivity beyond just faster lab results

- Improved resource allocation

- Streamlined processes throughout the production chain

By embracing this holistic approach, manufacturers can stay competitive in an increasingly complex market. Now is the time to think bigger and smarter about how we approach efficiency in manufacturing.

Gaulthier Pesneau: For example, aseptic processes run at a very high speed, and an error – even if it’s rare- can have a big impact on the bottom line, and the sooner the better when it comes to being alerted. The second step is to immediately understand the root cause and treat it...because every second counts and restarting a line is a critical moment and decision.

Q: Can you share some more details? What does going ‘further’ mean?

Gaulthier Pesneau: Gone are the days when quality control meant being chained to a laboratory. Going ‘further’ takes testing out of the lab and onto the production floor. This shift is not just a change of location; it's a complete rethinking of the testing process.

Rapid microbiology results can be implemented at many stages, from incoming raw materials to real-time monitoring of the effectiveness of sanitation practices, to processing and packaging. An appropriate sampling and testing plan allows manufacturers to assess the microbial load in different areas of the facility, identify potential contamination hotspots, and make necessary adjustments. This proactive approach helps to prevent microbial issues before they escalate, ultimately resulting in a more consistent, higher quality end product with a longer shelf life; fermented products may strongly benefit from this as shelf life remains a key issue for retailers and a key differentiator.

Franck Andrieux: Going further is not just a matter of time, because the precision of the information can change the game when it comes to making decisions. There is a gap between what the analysis says and what the decision-maker needs. Filling this gap has tremendous value and is where "going further" makes sense. If you think of "fruit juices" or "sports drinks" (on the rise!), this is where bioMérieux has made a difference with its innovative xPRO ACB offering, providing manufacturers with risk-based information on the "real spoilers".

At bioMérieux, we strongly believe that a fast result is not enough, it must be integrated into an effective testing plan and processes: at the right time, at the right location, at the right quantity. For example: when and where is my testing relevant, how many, and how much do I need to test to be representative? Basically, it's not about getting a quick result, but how can I make the most of it?

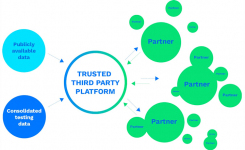

Going "further" also means that data is all around us, and little of it is being analyzed and used... and it's time to unlock its value! By using effective digitization within the company, rapid microbial results can be communicated quickly and effectively to all areas of production, helping to develop a culture of continuous improvement and awareness of microbial issues.

Q: How is bioMérieux ready to support Dairy and Beverages manufacturers and what is the game changer?

Gaulthier Pesneau: bioMerieux’s Augmented Diagnostics approach is the game changer. And it's not always faster, because Augmented Diagnostics can enable action before it happens.

This approach is the combination of cutting-edge microbial testing technology, the latest data science & genomic methodologies as well as an innovative spirit and experts to support dairy and beverage industries. From detecting spoilage contaminants in products or on surfaces to pathogenic organisms. Leveraging a combination of industry insights, bioinformatics, metagenomics to deliver unmatched value and data-rich insights for dairy and beverage manufacturers.

Franck Andrieux: Augmented Diagnostics is a revolutionary approach and bioMérieux can help change the game through:

- Raw materials and Ingredients management: provide clarity and insights to anticipate upstream risks. In Dairy & Beverages, sorting and prioritizing raw materials as well as ingredients can significantly reduce unforeseen events along the manufacturing process.

- Manufacturing Excellence: Faster and more meaningful insights to take better and faster action, reduce product hold-times and plant down-times, and improving process reliability. Knowing your defect faster and better is key. Combining bioMérieux diagnostic solutions to cleaning & sanitation procedures can improve efficiency and reduce costs and chemical usage.

- Product Quality & Consumer Protection: To detect, anticipate and prevent microbial risks, bioMérieux solutions help protect brand exposure by increasing knowledge of the finished product. Peace of mind for the entire organization, including supply chain managers, with fast and secure approvals.

Q: How does Augmented Diagnostics help identify root causes and take preventative actions?

Gaulthier Pesneau: One example is our Data & Genomics offer, which is designed to transform the approach to product safety and innovation with:

- Spoiler Mapping: Know your spoiler better. Root cause analysis of bacterial isolates in raw materials, products, and factory environments. Are there persistent strains or biofilms in my factory? Is biocide resistance an issue?

- Pathogen Mapping: Know your pathogen better. Root cause analysis of bacterial and fungal isolates in raw materials, the product, and the factory environment. Is the pathogen resistant to cleaning treatments?

- Microbiome Discovery: Better to know what’s in it. Identify pathogens/spoilers from a beverage, dairy or solid food sample containing a mixture of organisms

Remember, you are not just investing in a tool, you are investing in a paradigm shift in quality management.

Q: How Does Augmented Diagnostics help top executives achieve their business goals?

Franck Andrieux: Augmented Diagnostics speaks everyone's language and to everyone.

Augmented Diagnostics doesn't just meet the expectations of the quality department, it also contributes to the company's overall objectives. In today's competitive business environment, quality and cost effectiveness are the twin pillars of success. However, getting buy-in from top management for changes in quality processes can be challenging, especially when capital investment is required. Augmented Diagnostics, however, can present complex data in a crystal-clear, easy-to-understand format, allowing you to communicate confidently with management so they can make quick, informed decisions to optimize processes and calculate the improvements to the bottom line.

By simplifying complex testing procedures, we're putting the power of diagnosis in the hands of the entire team. This empowerment results in a happier workforce and significantly reduced turnover. Employees who feel they're making a meaningful contribution are more likely to stay and grow with the company.

By securing top management buy-in for quality process changes, you don't just improve operations - you revolutionize your entire business model. The return on investment becomes clear, as each adjustment translates into measurable success.

Q: In summary, what are the key takeaways here?

Franck Andrieux and Gaulthier Pesneau: Insight data that AUGMENTS value to DIAGNOSTIC findings highlights risk and helps manufacturers make better, more informed and faster decisions.

Take the first step towards revolutionizing your quality management today. Your bottom line will thank you! Use the Request Information button below.