Listeria monocytogenes is a ‘zoonotic pathogen,’ meaning it can spread between humans and animals. It is among the leading causes of death from foodborne illness with a 15% to 30% case-fatality rate. While Listeriosis is quite rare, many types of food and food processing operations are vulnerable to the organism, which has its natural home in the soil upon which animals graze. Unlock the hidden potential of your environmental monitoring with NEMIS Technologies’ new rapid test for Listeria monocytogenes, which is currently commercially available in Switzerland, France, Spain, and Italy.

Listeria monocytogenes in your production environment

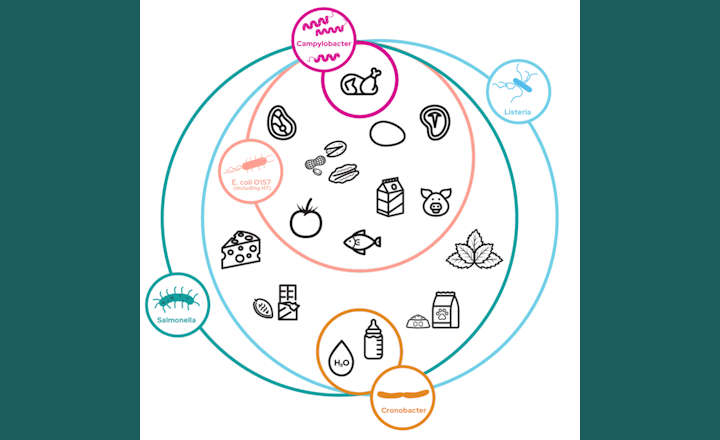

Any type of raw meat can contain a variety of different pathogens. At the start of the meat production process, pathogenic organisms can transfer on the freshly slaughtered carcasses and then spread onto primal cuts. Raw meat cuts are typically converted into finished products through a rich diversity of technologies and recipes. Even if the carcasses are not contaminated or cooking and fermentation successfully eliminate the pathogen, the risk of cross-contamination remains. It has been well-established that Listeria monocytogenes can become firmly ingrained in equipment and the factory environment. According to food hygiene and safety expert Dr. Jeff Banks, the most significant risk for the meat industry is cross-contamination. To fully assess and effectively manage this invisible risk, appropriate control points (HACCP) should be identified, and the precise locations and behavior of Listeria monocytogenes in meat plants understood.

NEMIS Technologies AG has produced this short informative video explaining where Listeria monocytogenes is most commonly found in the production and processing of meat.

Three areas of increased risk in your meat production process

1. Cooking

Cooked meat is susceptible to contamination with Listeria monocytogenes. The cooking process of hams, pates, and comminuted meat ‘logs,’ for example, eliminates most pathogenic bacteria, providing Listeria with the ideal growing environment. Thus, if any cross-contamination occurs between the cooked meat and unsanitary equipment or environment, Listeria monocytogenes has a highly nutritious medium in which to multiply. Therefore, hygiene must be paramount in zones where cooked meat is knocked out of the metal molds and during grilling or smoking steps.

2. Fermentation

Fermentation is a technique that is centuries old. It relies on natural microorganisms and defined starter cultures, which help acidify the meat by utilizing fermentable carbohydrates. Raw, dried, and fermented meat products have a long history of safe consumption, and traditional recipes and processes can eliminate Salmonella and E.coli. However, if raw meat is heavily contaminated, the fermentation process might not eliminate Listeria monocytogenes completely. If the pathogen is still present in low numbers, it is possible that the routine sampling might not even detect it. In addition, many of these raw meat products will not support the subsequent growth of Listeria monocytogenes because the moisture content and acidity are too harsh. However, the fermented products can still cross-contaminate other equipment and spread Listeria to other more susceptible meat products, e.g., cooked meat.

3. Slicing and dicing

High-speed slicing or dicing machines in the industrial meat processing supply chain are the standard. Typically designed and operated for volume throughput, these machines can be challenging to clean and sanitize. Listeria may become deeply ingrained in the equipment and evade detergents and disinfectants, sometimes only re-emerging once the machines generate sufficient heat to melt the animal fat and release the microbial contamination from inside bearings and between metal and plastic parts close to the slicing and dicing blades. Regular swabbing of this equipment is needed to find the root cause of persistent, low-level contamination.

Take your environmental monitoring to the next level

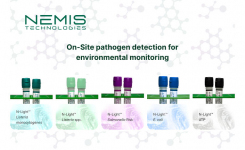

N-Light™ Listeria monocytogenes is a qualitative test method for the rapid detection of Listeria monocytogenes in food processing areas, which allows for immediate corrective actions thanks to short time-to-results. The N-Light™ system is designed to free you from the constraints of laboratory infrastructure and the dependence on external partners by enabling safe on-site testing anytime by anyone.

What do our customers say?

“With the N-Light™ Listeria monocytogenes rapid test, we have found a method that allows us to perform an efficient Listeria monitoring in our production facility. The application is user-friendly and provides reliable results in a short time. This helps us enormously to ensure food safety in our products.” - Angela Stadelmann, Quality Manager Metzgerei Angst AG