With the onset of the 2020 pandemic, humanity has opened a chapter of the incomprehensible. But, even before it could come to an end, some of the largest European food producers are making headlines with product recalls.

Corona virus and the paradigm shift to preventive diagnosticsEurope has seen a 13% increase in food recalls in 2020, with the average cost of such a product recall estimated at EUR 7-8 million. Even today, 600 million people fall ill each year from contaminated food, with children under 5 being the most affected (WHO).

Over the past two years, the Corona virus has sparked a trend toward preventive diagnostics in public health. In retrospect, it appears that many states tested too late and too little. As a result, routes of infection were not detected early, and the virus was able to spread unnoticed. In addition, reliance on overburdened service laboratories limited the effectiveness of many measures. If we could start over with today's knowledge, the first and most important measure would probably be to test as often and as early as possible; and do so directly from home. With the right technologies, this approach offers tremendous opportunities in the food industry.

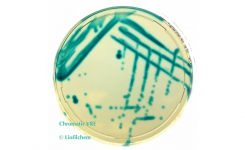

Not even the Big Players are immuneE.coli in frozen pizza, salmonella in infant milk formula, and children's chocolate - the scandals of recent months have shown that even the big players in the food industry are not immune to safety and quality challenges. Insurance measures against damage such as a product recall cost the market billions, all in an attempt to protect against uncertainty and unseen risks. According to French authorities, conditions at the pizza factory in France were inadequate, highlighting the importance of environmental monitoring. A preventive approach is essential for checking cleaning and hygiene, as well as continuous control of production areas. The cost of inadequate process control is incredibly high because when it comes to food, it is not only counted in monetary terms but quality of life or even human lives.

Not only does the food industry test too late (e.g., finished products waiting for delivery or already in supply chains), it tests too little. Analyzing a single-digit number of food samples from tons of food is never representative. Moreover, focusing on testing final products is statistically meaningless and uneconomical; it may give the good feeling of "having done something," but it rarely protects public health or brand reputation.

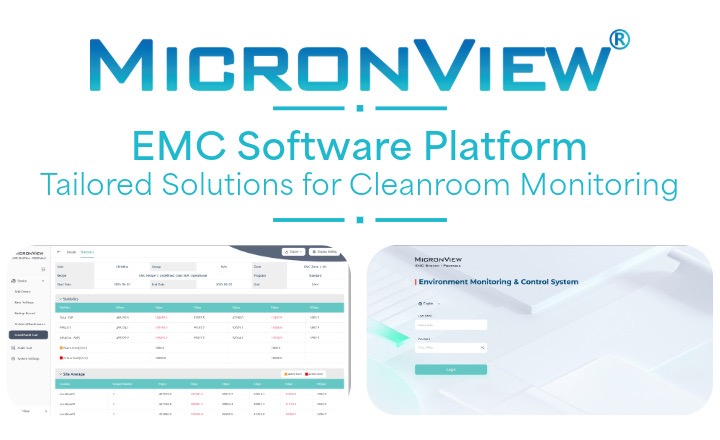

New technologies allow for new approachesWhy aren't many more checks made at the source of contamination, i.e., in the production environment itself? The reason is that microbiological investigations require a laboratory infrastructure and thus high investment costs. Accordingly, it is not surprising that the vast majority of food manufacturers outsource the analysis of their environmental monitoring.

NEMIS has reinvented the detection of pathogenic bacteria and enables the approach proven by the pandemic: complete control through rapid tests directly on-site to take adequate measures quickly. Whether you rely on an external service provider or use an in-house laboratory, the N-Light™ Listeria monocytogenes offers both a competitive and complementary approach. Waiting for results from outside laboratories can take up to five days. The NEMIS rapid test allows the implementation of initial measures after only 24 hours and an increase in the number of analyses within the same budget. On the other hand, by detecting live bacteria, the approach also complements existing PCR testing programs. Furthermore, since the test can be performed on-site without formal training, the number of samples and timing can be flexibly chosen according to specific and immediate needs.

Last week NEMIS proudly presented its innovative system for rapid and reliable detection of pathogenic bacteria at the European Symposium for Food Safety in Munich. The young company met with key decision-makers and industry experts to introduce a long-overdue paradigm shift in the food industry.

To discover the Listeria rapid test click here or use the green "Request Information" button below.