Alkaline phosphatase (ALP) is a naturally present enzyme in all raw milk types. It catalyzes the dephosphorylation of many types of proteins and nucleotides. Since the heat required to inactivate the enzyme exceeds that of most microbial spoilage organisms, it serves as a powerful indicator of successful pasteurization (when paired with rapid cooling). In fact, inactivation of this enzyme to an acceptable level is used to measure effective pasteurization. This value varies among different pasteurized milk types: < 350 mU (milliunits)/L for cow's milk (ISO Standard 11816-1), < 300 mU/L for goat's milk, and <500 mU/L for sheep's milk.

ALP measurements above these levels would be considered indicative of a significant issue in the pasteurization process or suggestive of post-pasteurization contamination. Because ALP is more heat stable than most pathogenic organisms, ALP can serve as an indicator of overall product safety, although it cannot guarantee that the tested product is completely free of undesirable microorganisms.

Advances in the last few decades have allowed for the development of more robust procedures for detecting ALP in pasteurized milk products. In general, these assays contain a substrate that contains a phosphate group. After cleavage by ALP, the substrate is converted to a fluorescent or light-generating compound. The level of fluorescence or light is then read by the system's instrument, displaying values that are proportional to the activity of ALP in the sample. These systems are much more rapid, practical, and sensitive than older colorimetric methods and allow for much lower levels of ALP to be detected.

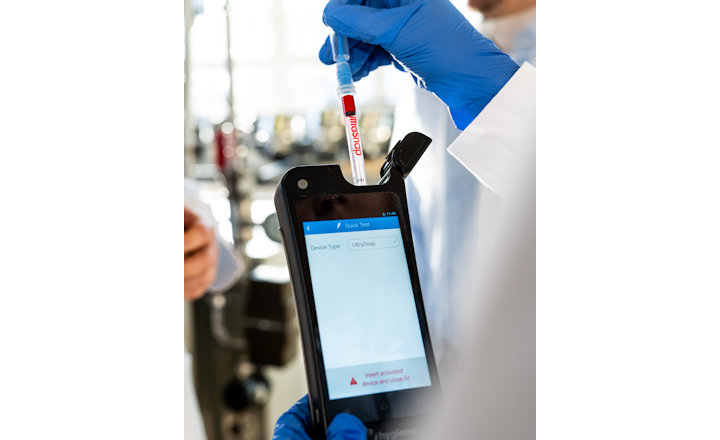

One robust test is ZymoSnap ALP from Hygiena®. It is a rapid, bioluminogenic method that determines the level of ALP enzyme activity in 5 minutes using a simple three-step procedure. The assay uses a single, self-contained device in one simple procedure. A sample is added to the ZymoSnap ALP tube, the device is activated to release the detection reagent, and is incubated for 5 minutes. The resulting ALP enzymatic activity is measured in a luminometer, specifically, the EnSURE® Touch.

The EnSURE Touch then converts the Relative Light Units (RLUs) to milliunits per liter (mU/L) of ALP in the pasteurized milk sample. Typically, values below 100 mU/L will give a pass result, values above 350 mU/L will give a fail result, and results in-between will show a caution result. These limits align with the regulations for post-pasteurization ALP levels. To establish your own Pass/Fail criteria, a positive and negative control must be prepared using the ZymoSnap ALP Positive Control Kit and tested prior to testing any unknown sample. Currently, ZymoSnap has been AOAC-approved and is awaiting NCIMS approval.

As a bonus, the EnSURE Touch luminometer supports other tests for hygiene and allergen monitoring, all with applications in dairy manufacturing operations, providing a cost-effective system for any dairy facility. In addition, the instrument is self-calibrating, requiring little to no maintenance or servicing, reducing costs even more. Furthermore, data can be stored in Hygiena's SureTrend® Cloud (SaaS) data analysis software to track, trend, and analyze test results, automatically generating reports and maintaining records for audit compliance.

Learn more about ZymoSnap ALP here or use the green "Request Information" button below to contact the supplier for details.