In modern dairy production, contamination is not merely a food safety issue—it's a business risk that can compromise profitability, disrupt supply chains, and damage brand trust. Traditional culture-based methods, while historically valuable, often introduce significant delays and hidden operational costs. As dairy processors strive to meet increasingly stringent safety standards while preserving margins, it becomes crucial to rethink pathogen detection strategies.

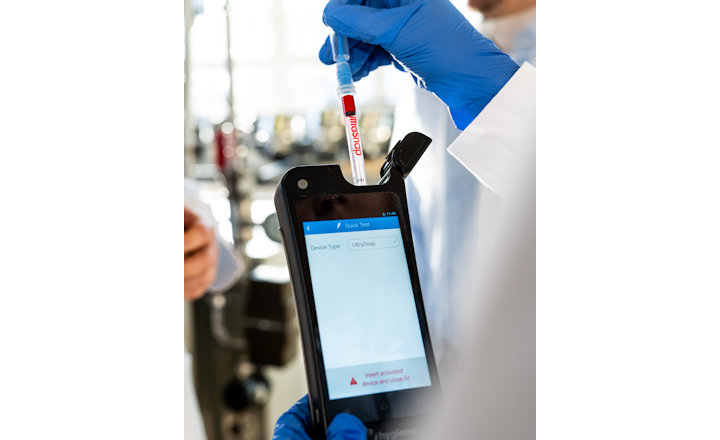

This article outlines how integrated rapid testing systems can streamline quality control, reduce contamination risks, and drive tangible returns on investment (ROI) for dairy producers. Drawing on Hygiena's experience in global dairy safety programs, we examine technological advances that enable faster, more reliable contamination detection from farm to final product.

The Limitations of Traditional Culture-Based Testing

Conventional pathogen detection in dairy relies heavily on culture enrichment, requiring multiple days to generate results. This latency extends product holds, ties up storage capacity, and delays release decisions, affecting cash flow and logistics. Beyond time constraints, manual plating methods are labor-intensive, subject to human interpretation, and prone to false positives/negatives due to stressed cells or competitive microbial interference.

While consumable costs may seem modest, traditional testing incurs hidden expenses, including:

- Labor-intensive sample preparation (e.g., multiple dilutions for MPN testing)

- Large incubation space requirements driving up utility and overhead costs

- Increased likelihood of production downtime or recalls from undetected contaminants

The risk of undetected contamination or unnecessary product holds affects not only operational efficiency but also regulatory compliance and market reputation.

Rapid Testing: Common Pitfalls and Industry Gaps

Though rapid testing solutions have entered the market, many offerings are limited in scope—focused narrowly on select pathogens without addressing the broader spectrum of dairy contaminants, such as allergens, spoilage organisms, or hygiene indicators. Fragmented test systems often lack integration, preventing processors from obtaining a complete, real-time view of their quality status.

This fragmented approach leaves dairies vulnerable to:

- Unmonitored contamination pathways (e.g., cross-contact allergens, environmental biofilms)

- Delayed corrective actions due to disconnected data silos

- Missed opportunities for proactive risk management and resource optimisation

Integrated Testing: A Holistic Approach to Dairy Quality Management

Hygiena’s comprehensive testing platform addresses these gaps by providing an end-to-end solution that spans raw material intake, production environments, and final product release. Beyond supplying rapid tests, Hygiena’s Applications Labs in the US, Germany, and UK partner with dairies to validate protocols for emerging dairy products, troubleshoot atypical results, and tailor contamination control strategies to specific processing environments.

With the dairy sector under constant pressure to balance safety, efficiency, and profitability, adopting a unified, validated rapid testing platform is no longer optional—it is essential. Leveraging advanced diagnostic tools and data integration allows dairies to transition from reactive testing to proactive quality assurance, securing long-term ROI and market competitiveness.

Interested in learning more?

Contact Hygiena to explore how integrated rapid testing can safeguard both your dairy’s products and profits.