Extending the shelf life of food products has been a crucial objective for manufacturers for decades. Ultra-High Temperature (UHT) treatments, a key process to achieve commercial sterility, enable the production of food products with exceptionally long shelf lives, often exceeding 12 months. Initially popular in the dairy industry, UHT treatments are now widely adopted by manufacturers of plant-based beverages and stocks.

Commercial sterility refers to "the absence of microorganisms capable of growing in the food under normal non-refrigerated conditions during manufacture, distribution, and storage” (Codex Alimentarius Commission (WHO/FAO) CAC/RCP 40-1993). This editorial explores various testing methods used to confirm commercial sterility in UHT products.

Maintaining food quality and safety is essential, and microbial contamination in UHT products, including dairy and plant-based milks, yogurts, creams, and stocks, poses a significant challenge. To address this, both traditional and innovative approaches have been developed for detecting microbiological contaminants.

The traditional method for verifying sterility in finished products involves total bacterial count. The procedure includes:

- Pre-Incubation: Packages are incubated for three to five days at 30 °C and 55 °C.

- Plating: Samples are plated on a generic agar such as plate count agar.

- Secondary Incubation: Plates are incubated for two days at 30 °C and 55 °C.

- Analysis: Colony enumeration confirms the absence of microbial growth.

Products are released only if no microbial growth is detected, demonstrating commercial sterility. However, this method is time-consuming, labour-intensive, and costly due to extended storage periods. Consequently, UHT manufacturers are increasingly adopting faster, less laborious alternatives that can maintain the accuracy of traditional methods.

Several rapid testing methods for sterility have emerged, including pH measurement, ATP testing, CO2 monitoring and Flow Cytometry. Each method offers distinct advantages and drawbacks.

- pH Testing: Following incubation (3–5 days at 30 °C and 55 °C), the pH of samples is tested. A significant pH drop indicates contamination. This method is cost-effective and requires minimal equipment but is limited to detecting acid-producing microorganisms and is unsuitable for acidic foods like juices. It is also labour-intensive and time-consuming.

- CO2 Monitoring: This approach measures CO2 levels, which rise during bacterial growth, using a colorimetric or fluorescence-based reaction. Samples are inoculated into proprietary media and incubated within an instrument. Results are available in two to four days, reducing holding times. This method requires minimal labour and conserves lab space through automated incubation; however, it has limited sample throughput due to instrument capacity. The initial set-up costs and the cost per test are high.

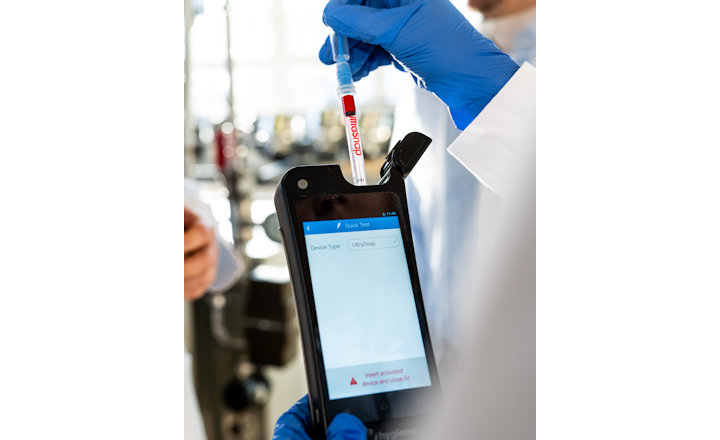

- ATP Testing: ATP testing detects microbial contamination through light emitted during a bioluminescence reaction. The process involves removing free ATP, lysing microbial cells, and measuring bacterial ATP using a luminometer, all of which is performed in an instrument. (such as the Innovate™ System from Hygiena®). This method supports high throughput, processing 96 samples in under 20 minutes. It significantly reduces holding times by at least five days and is user-friendly and cost-effective. Even though it entails higher initial set-up and equipment costs, the cost per test is low.

- Flow Cytometry: Flow cytometry is a technique that can be used to test for sterility in samples such as blood products. Bacterial cells are labelled with a fluorescent dye. The labelled cells pass through a laser beam in a narrow flow cell and are detected by the flow cytometer. However, the method doesn’t support high throughput testing as well as ATP testing. The initial set-up cost can be very high and on a cost per test basis, this is the most expensive method. However, it requires less labour and provides accurate results.

Selecting an appropriate rapid microbial screening method depends on several factors:

- Speed and Reliability: Opt for a method that delivers quick, reliable results to enhance operational efficiency.

- Laboratory Efficiency: Choose methods that minimize manual input, support automation, and offer high sample throughput without excessive space requirements.

- Technical Support: Ensure providers offer comprehensive support, regulatory compliance assistance, and expertise in the food industry.

- Regulatory Compliance: Ensure the system integrates seamlessly with Laboratory Information Management Systems (LIMS) and Enterprise Resource Planning (ERP) systems, meeting regulatory requirements for data tracking and reporting.

- Continuous Improvement: Partner with providers committed to continuous improvement in instrumentation, software, reagent stability, and application development.

The pursuit of efficient, accurate, and cost-effective methods to ensure the commercial sterility of UHT products continues to evolve. While traditional methods remain reliable, rapid methods such as pH testing, ATP testing, Flow Cytometry and CO2 monitoring offer compelling alternatives to meet the dynamic needs of the food industry. By selecting the right method and collaborating with innovative solution providers, manufacturers can improve product safety, reduce costs, and enhance operational efficiency.