Microbiology has always been very traditional and very labour intensive with the view that automation was for other disciplines but not suited for microbiology. Over the last few years, however, new and improved automated technologies have provided solutions to the challenges facing today's microbiology lab. The first stand-alone automation for the micro lab was introduced in the 1950s, with the initial systems primarily designed for blood cultures, TB, antibiotic susceptibility, and biochemical based identification.

It wasn't until 2006 that the first true bacteriology automation was introduced with barcoding of dishes, inoculation, moving tracks systems, automated incubation, and digital imaging. Like many other industry advancements, laboratory automation is designed to increase efficiency, streamline processes and deliver high-quality, consistent results in less time.

Today, automation is a complex integration of computers, robotics, liquid handling/processing, and other combined technologies. Automation of routine procedures such as dedicated workstations and software to program instruments has already impacted laboratories worldwide. With repetitive tasks such as pipetting, transporting plates, and various types of assay being the first to be automated.

What's Driving the Shift to Microbiology Automation? Each lab probably has it's own issues, but the main factors are the continued pressure on reducing costs whilst increasing productivity, turnaround time, and result reliability. The current trend is towards merging smaller labs into large super labs, which are considered to be the most cost-effective and efficient way to process samples, and these have the advantage of creating centers of excellence in terms of expertise.

With the shift from country-specific accreditation to the more demanding international ISO 15189:2012, automated systems are ideally suited to meet accreditation requirements by automatically monitoring each step of the analysis, retaining the data for later access. Recruiting and retaining qualified, experienced staff, especially with a trend towards 24/7 working, is also an issue for many labs, so again automation can step in.

So What Steps can be Automated?

Media Preparation: Perhaps the most well established and long-standing area that can be automated is media prep, however now often, labs will not see this as a core activity with all the associated validations and QC and will buy in ready to use media.

Specimen Prep - Planting/ Inoculation/Streaking Plates Most fully automated inoculation and streaking systems require liquid transport swabs or liquid samples. Specimens can be loaded into racks and then loaded onto the instrument; alternatively, samples can be added to a turntable for continuous loading. The sample is scanned, and the system will know how to process the specimen and what plates are required.

After vortexing the required plates arrive ready barcoded so that they can be tracked and traced throughout the process. Plates are then planted/inoculated or streaked depending on what was specified for that particular specimen. A HEPA environment ensures no cross-contamination. Specific streaking patterns can be pre-programmed and achieved by robotic loop. This results in a consistent, reproducible inoculation and streaking pattern and produces single colonies more often than by a manual process, with the benefit of reducing the incidence of operator RSI.

Systems will include a monitoring step to ensure that some sample has indeed been taken up by the pipette or loop. Inoculated plates can then be sorted according to required atmospheric conditions and temperature and transported by conveyor belt to the appropriate incubators.

Any non-liquid or other specialized samples can be done in a semi-automated fashion whereby the technician prepares the plate, which then goes back into the system with the bulk of samples.

Artificial Intelligence

Artificial Intelligence can be applied to screening and interpretation of plates following incubation; algorithms can be adjusted to meet a particular lab's requirements to enable the automated screening of non-critical plates, depending on visual appearance, sample or patient histories, etc. This results in the vast majority of plates being automatically read and recorded without the need for any technician intervention.

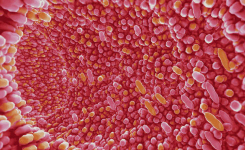

Incubation As each plate is barcoded, on the way to the incubator, it's scanned so incubation start time is registered and how long that plate will need to be incubated before going to the plate reader. Plate Reading and Interpretation After incubation plates are automatically moved to the image analyzer for reading and may subsequently be returned to the incubator if necessary, this means plates get exactly the correct incubation time even if due for reading during the night if the lab is 24/7. The barcode on the plate contains information on which camera and lighting settings are required to take images for that particular plate. Even chromogenic plates, such as for MRSA, can be automatically read and interpreted. The whole plate set from a patient can be put together on one screen for viewing together in one place, so secondary plates such as antibiotic sensitivities can be seen with the primary plates, or the image from day 1 can be viewed with day 2. Images can be saved for later reference or auditing purposes.

Looking at plates on a screen is probably one of the most significant changes that automation brings for the biomedical staff who are used to holding a plate, seeing it in 3D, and maybe quickly doing some basic biochemical tests. But plates can always be called up to the workbench for examination by eye, and as staff gain more confidence in the digitized system they will most likely need to only call up those plates that are necessary, leaving the bulk routine plates to be handled by the instrument.

Antibiotic Sensitivity Testing The inoculation and streaking modules are able to produce seeded plates for sensitivities. However, the relevant antibiotic sensitivity discs need to be added using traditional disc dispensers. These plates can be returned to a workbench for the discs to be added.

Identification is typically performed by matrix-assisted laser desorption/ionization time-of-flight (MALDI-TOF). MALDI–TOF has been one of the great advances in microbiology in recent years due to its speed of result together with a low cost per test it easily outperforms biochemical based approaches. Most MALDI–TOF will sit near or immediately next to an automated system, and some systems can use a loop to seed the MALDI –TOF target plate automatically.

How is Automation Different? In most inoculation and streaking systems that are fully automated, the samples first need to be in a liquid format (i.e. liquid transport swab, urine), although other types of specimen can fit in later in the process. The common perception is that digital imaging can be used to make a determination. In fact, it is used to sort the plates, which maybe of interest to do further work or sensitivity testing. The others can be sent to discard without being handled by a biomedical scientist. There will always be some plates that may require a visual check by the laboratorian prior to doing any further work being performed.

With automation, a majority of manual processing of bacteriology is removed and reading using digital imaging is different and takes some getting used to by biomedical scientists. Automation changes the workflow of the lab by allowing continuous flow processing as opposed to batch processing. This is a move from the traditional approach of reading plates in the morning and setting up plates in the afternoon and is more compatible with a 24/7 operation.

The centralized processing and reading gets away from the traditional specialized benches or areas, staff can easily access all the data from a particular sample and compare on one screen. It also frees trained, experienced staff from doing dull repetitive tasks they can be usefully employed in using their skills and knowledge where it is most needed - in the unusual results rather than the routine ones.

Advantages of Lab Automation Include:

- Increased productivity, more samples processed per person

- A move away from batch processing to continuous, even 24/7 processing

- The ability to handle surge demands

- Remote reading and access to images of plates and organisms

- Assurance that the sample is processed correctly with the right plates and incubation conditions

- Ability to view the whole patient's plate set and historical plate sets

- Reduction in technical and transcription errors

- Improvement in traceability and fully audit trails including the reading process

- Images available for retrospective and training purposes

Systems Available

Larger automated systems are modular and can be configured to fit into the available laboratory space. Quite often, the systems must be built to specific design specifications. However, the inoculation and streaking modules have a fixed footprint and are available off-the-shelf. Additional modules can be added on, which include the fully automated transport of plates to fully-automated incubators. Many of these systems will have a lead in time, however this allows time for the lab to prepare for the change and complete any enabling works.

Conclusion

So you think you should look at automating your lab? Certainly, in the current climate, only labs that are most fit for purpose and cost-effective will survive. Use this checklist to get an idea of what points to consider.

Building Your Business Case– The Automation Checklist.

What is the Pay Back time or Return on Investment?

- How many staff can I save?

- Need to consider enabling costs, IT interfacing and additional servers

- Consider delays in implementation

- Contingency requirements

- Surge requirements

- What are the risks to automation

- How long will it take to implement prior to realizing its full potential

Use the experience of other laboratories and simulation modelling to look at current test capacities and pinch points, what happens at surge peaks, what are the potential savings per test and in terms of workforce planning - will there be a reduction in staff through natural turnover or just better staff deployment?

IT

- Which type of interface is required, uni- or bi-directional?

- Is the interface already tried and tested or does it require development or customization?

- Does the automation company have middleware software that will link with other existing systems both within the micro lab such as MALDI-TOF and sensitivity instruments and with other labs?

Staff

- How do you allay the staff's fears about job losses?

- Do you have buy-in from the staff?

- How do you handle staff and samples during implementation?

Automation should not lead to de-skilling of staff but instead, remove tedious repetitive tasks from highly trained personnel and allow them to focus on using their knowledge and experience on results that need more in-depth interpretation with the advantage that they are able to view the whole set of results from that patient all on one screen.

Facilities

- Does the system fit into available lab space?

- Can the floor accommodate the weight?

- What impact will it have on the processing of other samples and tasks?

- Do you have a good project management system?

Measurement

- Have you benchmarked your current process in order to measure the productivity gains?

- Are you fully aware of the tasks and time requirements currently?

- What are the training requirements?

- Does the supplying company train everyone or a small number who then train the rest of the staff?

After-sales

- Does the company have good service engineering support?

- Is there a help desk? Is it 24/7 support?

- What are the response times to a critical fault?

- What is the contingency plan?

- How quickly can you get critical spare parts?

Customer support is key to making the right decision, you may be able to live with an instrument that is not exactly right for your lab but has great service support rather than a system that when working is perfect but has too much downtime waiting for a fix to technical issues.

Future of the Manufacturer/Supplier

- Is the company planning any future developments of the system?

- Is the company vulnerable to the competition or undergoing major changes?

Additional Checklist Questions

There are a number of key questions any lab will need to ask when deciding which is the best system and company for automation partnership. They should include the following:

- Do you want to automate the whole lab or part of it for specific areas?

- Do you want to choose one automation module now that can be added onto at a later date?

- What will be the impact of new technology in the future - such as Point of Care or molecular-based tests?

- Will this mean your current solution will become redundant in the future?

- Or will there be a technology switch in the future, so you are not able to realize its full potential and the savings?

- Which company offers the best solution to fit your own labs requirements?

- How quickly do you need a return on investment?

- Do you have a strong business case?

- What is the bigger picture? Will you become part of a superlab, therefore will you require additional capacity and expansion?

Get the latest updates in Rapid Microbiological Test Methods sent to your email? Subscribe to the free rapidmicrobiology eNewsletter